View of shop floor

View of shop floor

160 mm (6 5/16 inches) Plate being Hot Rolled

160 mm (6 5/16 inches) Plate being Hot Rolled

Orbital Welding Machine for Tube to Tube sheet welding

Orbital Welding Machine for Tube to Tube sheet welding

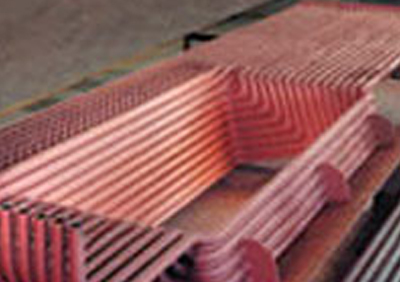

Membrane Panel for 170TPH Boiler supplied to Indonesia

Membrane Panel for 170TPH Boiler supplied to Indonesia

Deep hole drilling Machine (1000 mm thickness)

Deep hole drilling Machine (1000 mm thickness)

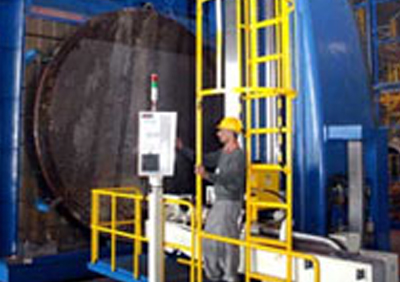

One of our four furnaces

One of our four furnaces Tensile testing machine

Tensile testing machine